Thorens TD 124

Critical Parts

THORENS TD 124 or TD 124-II is one of the finest classic quality products for playing vinyl records.

If you own this classic record player, you are very, very lucky! Thorens TD 124 is rare and in high demand.

The many years this gramophone has been in use and/or has been stored has an effect on its performance and your TD 124 no longer meets the original specifications.

Unfortunately, Thorens AG in Sainte-Croix no longer exists, which means that spare parts could also be a problem. But that is not the case for Thorens TD 124 and TD 124-II!

Schopper AG in Switzerland has produced spare parts for the TD 124 according to Thoren’s original specifications.

Production technologies have developed a lot in the past 40 – 50 years, this means that the very high quality and precision that Thorens has used to manufacture parts for the TD 124 can be significantly improved today.

This results in e.g. the main bearing for the plate plate today can be produced with much tighter tolerances than in the past.

Schopper AG has chosen to do that for spare parts for the TD 124.

You can get an overview of the components in the TD 124 that are critical for a perfect playback of vinyl records by reading further on this page.

All these products are produced by Schopper AG and can be supplied by Classic Audio.

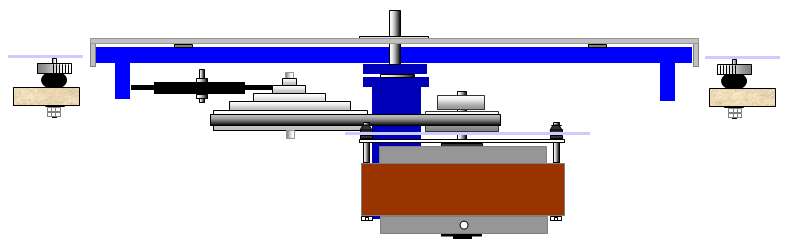

THORENS TD 124

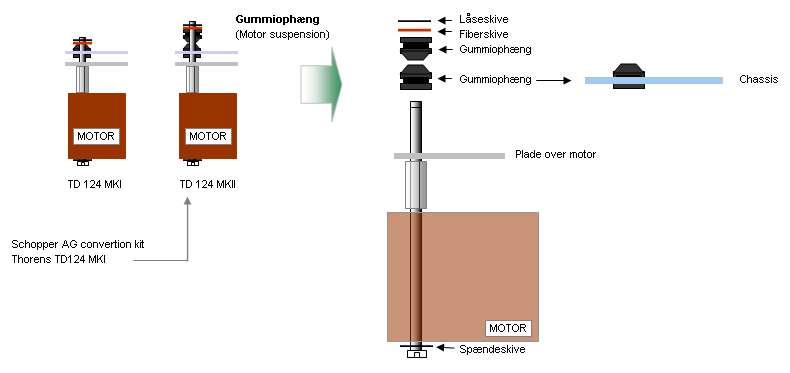

shown as a schematic drawing showing moving parts and suspension for MKI and MKII

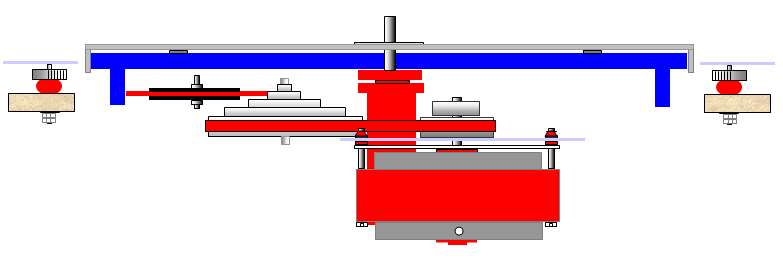

THORENS TD 124 – the most critical parts are shown marked in red

Note: All parts can be supplied by Classic Audio so you have the opportunity to refurbish your TD 124

Classic Audio can also offer a total refurbishment of your THORENS TD 124 if you do not want himself to carry out the rather extensive and demanding job.

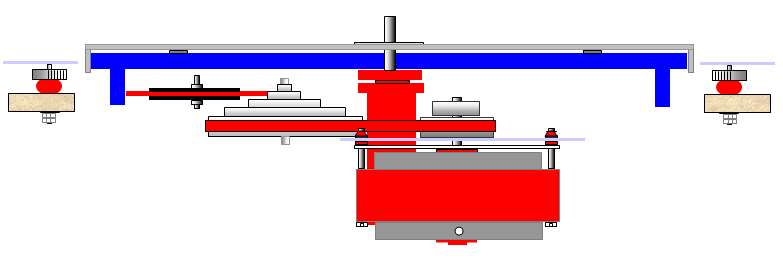

THORENS TD 124 – the most critical parts are shown marked in red

Note: All parts can be supplied by Classic Audio so you have the opportunity to refurbish your TD 124

Classic Audio can also offer a total refurbishment of your THORENS TD 124 if you do not want himself to carry out the rather extensive and demanding job.

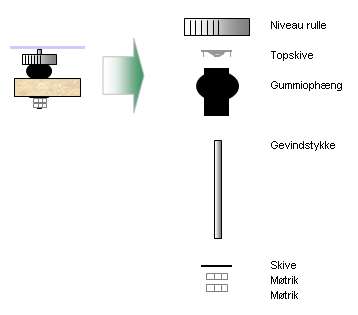

Rubber suspension for TD 124 / plinth – often referred to as “Mushrooms” must definitely be changed.

The rubber must be soft and have the correct shape.

The original suspensions certainly don’t have that after 40 – 50 years. It is very easy to change these, but it is important that the suspension is fitted correctly again.

Here is shown how the installation should be. This applies to TD 124 and TD 124-II.

Can be purchased from Classic Audio.

Rubber mounts for TD 124 / engine – it is very important for the noise called “rumble” that these rubber mounts are soft and new.

The suspension is very easy to change, and again it is important to mount the engine correctly after changing the suspension.

Below is how.

For the TD 124 MKI, the suspension is different from the TD 124 MK II. This is the reason why the MK I has slightly worse specifications than the MK II. You can actually achieve 4-6dB better specifications by converting the suspension for MK I to suspension like MK II.

Classic Audio can supply a kit for engine suspension.

Classic Audio also supplies a conversion kit for upgrading Thorens TD 124 to TD124-II

The engine is absolutely one of the most critical things for the TD 124.

It can be a very difficult task to renovate an engine correctly so that the optimum performance is left.

An engine must run:

- As quiet as possible (very – very low noise specification)

- Run extremely smooth (very – very low wow and flutter spec)

- High performance – power (The turntable must actually achieve the correct speed within one round of driving the turntable)

Oil – never use anything other than the original Thorens Oil – supplied by Classic Audio

It is an absolute requirement that the bearings are absolutely flawless and that a very precise calibration and centering of the motor has been carried out.

Classic Audio recommends sending the engine to us to get the right result

…or maybe you want Classic Audio to carry out the complete total overhaul of your TD 124

The main bearing for the turntable must be absolutely perfect and without damaging ‘bumps’ and scratches.

If you remove the plate plate WITHOUT loosening the screws that secure the plate plate and bearing, there is a very high risk of damaging the bearing.

Never do it!

Removing the bearing. It is best done like this:

- Remove the top platen

- Loosen the three screws securing the platen to the main bearing

- Remove the heavy platen

- Loosen the three screws securing the main bearing to the chassis (must be removed from the underside)

- At the bottom of the bearing there are three screws, they are loosened and the bearing is now accessible from both ends

- Now the bearing can be cleaned carefully with a soft cotton cloth

- Check that there are no scratches, nicks or other defects in the bearing – kit can be purchased from Classic Audio

- The rented house is assembled

- The bearing can now be lubricated again, do it with a pipe cleaner (carefully) and assemble the bearing itself

- Before assembly – always change the gasket and the bottom plates in the bearing

- After the bearing is mounted on the chassis, more oil must be added to the bearing. The shaft must actually be in a small oil bath. There must be approx. 1 ml of oil at the bottom of the bearing

- If the bearing is a sintered bronze bearing (Thorens TD 124 MK II after sn: 30000) it will be appropriate to use max. 2.5 ml, so that the upper bearing also works self-lubricating – the “free volume” in the bearing corresponds to 2.53 ml

- Assembly of the bearing and plate plates takes place in the reverse order of the description above

Oil – never use anything other than the original Thorens Oil – supplied by Classic Audio

Thorens TD 124 MKI for approx. sn. 15,000 and partly between approx. 15000 and approx. 30,000 was the main bearing for the turntable with plastic bearings. The biggest problem is that plastic bearings are easier to damage, and plastic bearings really require the correct oil for good lubrication.

Thorens TD 124 MKI after approx. 30000 has self-lubricating sintered bronze bearings, and the same applies to Thorens TD 124 MKII.

If there is a fault in the bearing, otherwise you want to upgrade to a new quality precision bearing, you can order it from Classic Audio

Classic Audio will be happy to carry out the complete total renovation of your TD 124

n intermediate wheel is actually quite critical to achieving a satisfactory result for the TD 124.

If the TD 124 has not been properly disconnected after use, there is a problem – for sure. The control button for speed selection must be set to – 0 – when the turntable is not in use, otherwise the intermediate wheel will stand and ‘press’ on both the aluminum step wheel and the turntable. The worst thing imaginable is if the record player has not been used for a number of years and an accident like the above has happened. Then the intermediate wheel is destroyed.

The intermediate wheel wears unevenly after a number of years and in some cases micro cracks occur and the wheel becomes ‘hard’. If the wheel is uneven but otherwise ok, it can in some cases be ground on special equipment, otherwise it must be changed.

Lubrication:

Never use anything other than the original Thorens lubricant – supplied by Classic Audio

Upgrading:

Classic Audio can now supply upgrade solutions for your Thorens

- Noise reduction kit for intermediate wheel

- New very high quality precision intermediate wheel