Classic Audio

Classic Audio renovation concept

A totally refurbished product means that the product has been brought to meet the same specifications as originally and appears visually as a new product.

The cabinet has been completely refurbished and without faults and appears as it did when the product was brand new from Bang & Olufsen. I achieve this by using fault-free parts from other Beolab / Beomaster / beovox products for the renovation or by a gentle actual renovation that e.g. can mean cabinet repair by a professional joiner.

A completely refurbished product plays in terms of quality exactly like the original product, i.e. the real and original HiFi sound.

You can hear how good the sound quality is, you can really hear a very surprising sound quality even compared to quality products sold today.

It is actually the case that the sound quality, dynamics and transparency you actually achieve for e.g. Beolab 5000 completely refurbished can be compared to products that today cost at least DKK 25,000.

A large number of components have been replaced, so that the sound quality is on par with good products produced today. Safety components and other components that have an influence on the lifespan are replaced, so that you can expect to use and enjoy the products for the next several years.

Classic Audio offers the opportunity to assess the result of the renovation in 2 ways.

- Certificate

A certificate is prepared that contains individual measurement results for the refurbished product in relation to

DIN 45500 and in relation to the manufacturer’s original specifications for the product. - The product

Visually, the product appears as new. As a customer, you have the opportunity to see this at a possible visit Classic Audio before making your decision.

A summary of the concept of total renovation of a Beolab plant:

- The cabinet appears as new

- A significant number of electrical components have been replaced

- The product is calibrated and adjusted according to B&O’s regulations

- A classic product that has been completely refurbished and tested for more than 500 hours before delivery

- A product that meets original factory specifications or better.

- Classic Audio Certificate – measure and test results for the product

- Instructions for use – quality scanned copy of the original instructions for use

- Diagram – quality scanned copy of the original B&O diagram in the correct version

- You will receive information during the process so that you can follow the product’s path to final certification.

- A personal website will be created for you, where you can follow the certification of your particular product

Total renovation of Beolab 5000

Cabinet renovation.Most cabinets can be renovated, but it requires patience and sensitivity to achieve a good result. | ||

| ||

Classic Audio replaces the painted end pieces and rear front panel with newly painted parts in the original color shade. Classic Audio has produced new anodized front panels for both Beolab 5000 and Beomaster 5000. | ||

Typical errors on components in the Beolab 5000. | ||

The components are changed because they are either degraded or will do so within a short time. | ||

Total renovation of e.g. Beolab 5000 | ||

And …… An example of a Beolab 5000 that cannot be certified. A Beolab 5000 that has been exposed to moisture is not stable in terms of quality and cannot be expected to have the expected lifespan after a total renovation. Rust formations can be seen in the pictures both inside the device and outside of the device. | ||

|

|

|

A Beolab 5000 is expected to play for at least 10 years after a total renovation. It will not be possible if it has been exposed to moisture. | ||

Total renovation of the Beovox 2500 Cube

In connection with a renovation of the Beovox 2500 Cube, there are 3 areas that are essential to focus on.

Cosmetic

Split filter

The speaker units

Cosmetic

The Classic Audio concept starts this way:

the Beovox 2500 Cube is completely disassembled in a gentle way. Loudspeaker covers are sanded and possibly dents or anything that can be repaired is carried out. The “cube” is made of solid beech wood. The cube is ground and possibly notches etc. are puttyed and sanded again. The chrome-plated foot and “stem” are uncovered. The cube and covers are then ready for painting.

It is done by a professional painter and the color is of course the original blue-grey Beovox 2500 color.

Split filter

The partial filter in the Beovox 2500 Cube is replaced.

New cable and DIN2 plug are installed.

Loudspeaker units

| The speaker units need special treatment in connection with the renovation. A typical example of the loudspeaker before a renovation. The speaker must be gently cleaned. The loudspeaker is then measured, where sound pressure and functionality are tested. Unfortunately, it is the case that approx. 20% of all speakers in the Beovox 2500 Cube are defective and must be replaced. It can only be done in one way, and that is to use another Beovox 2500 Cube as a donor. Unfortunately, the speakers are no longer available for purchase |

The speaker units must then be coated. This process is particularly critical and very essential | |

| The effect of this coating has 3 purposes

|

These improvements are essentially bringing the speaker back to its original specifications. | |

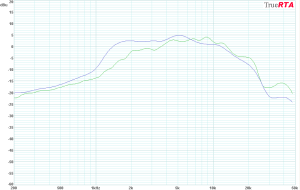

Here we show what can be achieved for the speaker in the Beovox 2500 Cube. The green curve shows the frequency response before the coating The blue curve shows the frequency response after the coating There is a very clear improvement in the area just above 2 kHz and the blue curve shows significantly better linearity than the green curve |

|

.

The base and stem are polished and then the Beovox 2500 Cube can be assembled, it is a very demanding process, where e.g. a very special “soft” glue is used to mount the speaker covers.

The result is really good.

Specifications have been obtained that match the original ones when the product was new.

This means that you have achieved a sound quality that is like when the product was new and it is possible to experience the quality of a Beovox 2500 Cube produced in 1967.

The cosmetic experience of a pair of Beovox 2500 Cube is “like new” and very – very nice!

It is fantastically nice to work with fine classic products like the Beovox 2500 Cube and achieve a really good result.

Total renovation of Beogram 3000

| Chassis BEFORE the renovation. The head bearing shows that the storage has not been good for this fine classic record player |

|

| A proper renovation requires EVERYTHING to be dismantled and cleaned very carefully. Here are all the individual parts before cleaning and replacing the defective parts | The new parts to be installed in the TD 124. Classic Audio replaces parts for approx. DKK 2500 – all parts are precision parts manufactured in Switzerland for the TD 124. |

| All parts are now carefully cleaned before assembly |

|

|

| An example of the result. Here a TD 124 painted in a nice red color. |

Engine renovation. It is the most critical and most difficult part of a renovation. Classic Audio strongly recommends that you do not start it if you are not an expert in the field. Renovation should definitely ONLY be done by professionals. |

| The engine must be completely disassembled and all parts must be cleaned very carefully. New parts are installed. Felt washers and bearings are changed (as needed) or bearings must be heated and old oil removed under pressure. The new oil must then penetrate the porous bearings – also under pressure. |

|

|

|

Here you can see all parts ready for assembly. After installation, the motor must be calibrated. It is a process that takes a long time. Getting this engine to run properly requires a lot of fine tuning and patience. |

| The tonearm on the Beogram 3000 requires careful and gentle renovation. Here are a few examples of how the individual parts may look before a renovation. The first picture is the arm lift. |

|  |

|

| The tone arm is disassembled. The thin wires are checked and tested. Bearing suspension is changed (gyro bearing) – the pinol bearing must be cleaned and adjusted very precisely. |

|

|

| Then the tone arm is reassembled, and now the individual parts must be calibrated very carefully. Lift height – tonearm movements and height in relation to the record plate and armboard – counterweight for needle pressure, etc |

| The finished result. The beautiful B&O tonearm mounted on an armboard for the TD124 MKII. The tone arm is mounted at the correct height in relation to the record and the turntable – the tone arm is calibrated for optimal anti-skating. The lift is mounted at the correct height. Counterweight is calibrated for correct needle pressure Note – armboard finish is rosewood veneer. | |

In connection with a certification, the TD 124 will be worked on for at least 15 hours, | ||

| If your TD 124 has not been treated well and has many scratches and surface defects, it can be painted. You can order the chassis painted in the original color or you can choose a completely different color – entirely according to your wishes. The result will be fantastic. Painting of the chassis can only be ordered in connection with a total renovation of the TD 124. |

|

|

| |

Here are some examples of the TD 124 painted in various very attractive colors according to customer wishes. |

| |

|

|

|

End pieces on the Beolab 5000 are always very scratched, the black back-front is always scratched and the front panels are often missing text or the edges are chipped and broken.

End pieces on the Beolab 5000 are always very scratched, the black back-front is always scratched and the front panels are often missing text or the edges are chipped and broken.