Thorens TD 124

Opgradering

The heavy plate plate on the TD 124 is an essential element in Thoren’s design concept. Thorens chose cast iron for the TD 124 series because of excellent properties such as: high density and damping capacity, great rigidity and extraordinary dimensional stability. These structural advantages that are so important to the Thor’s sound come with a major drawback:

this turntable is magnetic, which limits the choice of pickups.

Heavy pickups with strong magnets – like the Ortofon SPU – were pulled to the plate by magnetic attraction, in some cases so much so that it can damage the pickup’s tracking ability, and precise anti-skate is not possible.

To solve the problem, Thoren’s engineers in Sainte-Croix have experimented a lot with alternative materials for the turntable. Each of these attempts has resulted in a turntable that was either prohibitively expensive or sonically inferior to the original turntable. In the mid-60s, Thorens could offer to order a special non-magnetic plate made of pressed aluminium. The plate was produced by Inca a Swiss foundry that also produced the TD 124 chassis. In addition to the reduced weight (2.8 kg), the new turntable also meant distinct sonic disadvantages, namely high-frequency ringing! Therefore, the turntable was never offered as a standard component in the TD 124 series.

The only suitable material for a sonically superior non-magnetic turntable is “gray cast iron” iron with graphite flakes, a unique compound developed by the US military for demining operations during World War II. This unique alloy shows a 98% reduction in residual magnetism compared to standard cast iron.

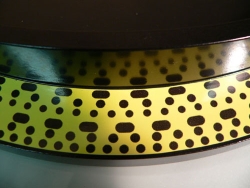

But today Classic Audio can offer a non-magnetic replacement plate weighing 5 kg – almost the same weight as the original – which surpasses the original in every respect. Our replacement plate is made from raw materials, chosen without compromise, followed by state-of-the-art casting, precision machining and finishing and accurate reproduction of the original strobe markings, all done by the best Swiss companies.

The new, non-magnetic turntable for Thorens TD 124 series I and II matches the original Thorens concept, at the same time with the advantages of:

- No magnetic influence on pickup coils or magnets

- Accurate, reliable anti-skating adjustment now possible

- Lower noise floor and radically improved dynamics

- Greater overall tonal balance and coherence

- Extended frequency response

- Tighter bass

- No restrictions when choosing a pickup

#1001

Here you can download PDF files with descriptions and test results:

Download a description of the antimagnetic plate

Download test results for the antimagnetic plate

The precision top turntable is built in fourteen distinctive operations instead of two (the original turntable). It provides a much better flatness, less wow and results in a nice sound image. After many trials with different alloys, our choice is an extra hard aluminum alloy, which reduces phase shift and therefore reproduces an extremely three-dimensional sound image even with mono recordings. The sound is far more dynamic with lower distortion.

- Soundstage – the sound image is significantly improved

- Dynamic range is improved

- Bandwidth is improved

- Rumble and needle noise are reduced

#1005

One of the most important elements in a record player is the bearing for the turntable – it is the lifeblood of any drive system. At the launch of the TD 124 MKI, plastic bushings were used in the plate bearing. The combination of the heavy rotational force of the drive system and insufficient tolerances for the rotating parts inevitably meant extensive wear.

For that reason, Thorens changed the bearing bushings to porous sintered bushings that functioned as an oil reservoir.

These bearings resulted in a reduction in bearing degradation caused by oil drying and bushing wear. However, after some time of use, wear and tear and noise are still a point.

While Thoren’s development department repeatedly experimented with alternative bearings over the years, management rejected all of these solutions for cost reasons.

We managed to get two prototypes from the former head of development in Sainte-Croix.

The development within production and processing and the point that there are no requirements for costs due to mass production have made it possible to realize the creative research result Thorens’ engineers had achieved.

Classic Audio can therefore supply a precision manufactured bearing for the turntable that really improves the TD 124 in the following respects:

- Dramatic noise reduction

- Improved specs for wow, flutter and speed variation

- Basic improvement of dynamic contrasts

- Tighter and more precise bass

#1201

The “Solid Design” plinth was developed to satisfy the demand for a massive plinth that can deliver real sonic improvements. Designed with full respect for the mechanical and aesthetic properties of the original Thoren plinth.

The plinth is made from two and a half layers of laminated, carefully aged, selected Swiss wood. The painting is with 8 layers of high-gloss varnish. The plinth can be supplied with either plastic, fixed feet or adjustable spikes.

In addition to spikes, the plinth is supplied with mushrooms (which disconnect the chassis from the plinth) and correct threaded pieces as standard accessories.

The “Solid Design” plinth brings about the following clear improvements:

- Acoustic feedback is almost eliminated

- A more balanced overall sonic presentation

- Tighter and more precise bass

- Basic improvement of dynamic contrasts

#2005